R-Proteika: Meat industry

This line of solutions is divided into 2 specific areas:

Agro

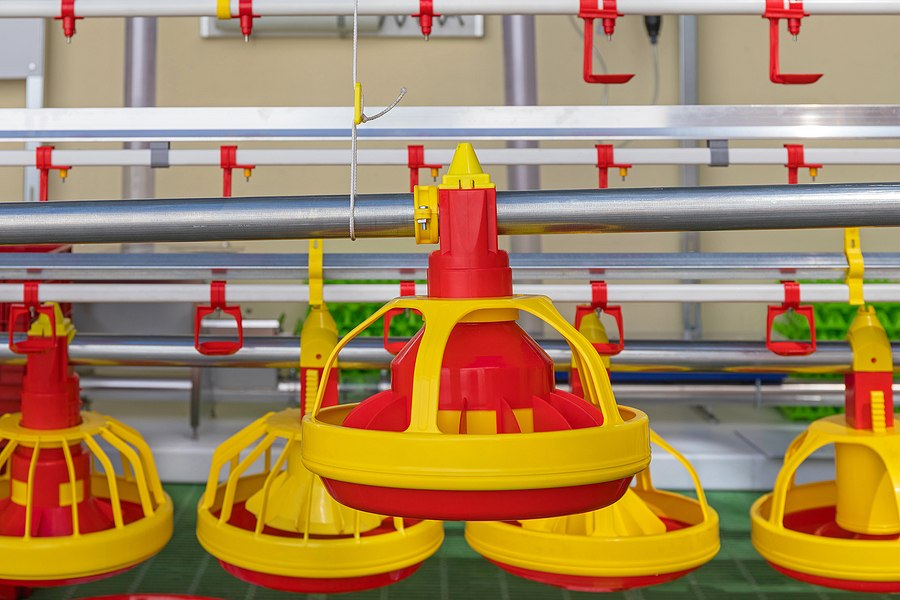

They are a series of solutions to meet the biosecurity needs (lower mortality) and higher productivity of the entire agricultural chain of the meat industry, from incubators and hatcheries, through their breeding and feeding to the slaughter process of those animals involved in this industry. This translates into considerable savings and higher profits for your business.

- Washing and sanitation procedures for incubators and hatchers

- Washing and sanitation processes of hydraulic systems

- Treatments for drinkers and feeders

- Washing and sanitation processes of direct application or with foaming

- Dry cleaning and disinfection procedures

- Washing and sanitation processes for trays, containers, and pallets

- Cage washing and sanitation processes

- Transport washing and sanitation procedures

- Poultry manure treatment

- Mortality management

- Measures to prevent cross-contamination and sanitary laundry

Industrial Processing

The products of this industry are highly susceptible to microbiological contamination of all kinds; sanitation plays a fundamental role from slaughter to reaching the point of sale. The care taken in each of these stages is decisive in terms of productivity for the company, especially in reducing waste, increasing product durability, and guaranteeing a safe product.

- Washing and sanitizing processes of CIP or water recirculation

- Methods of sanitizing and disinfection of fryers

- Washing and sanitizing procedures of IQF’s or freezers

- Cleaning and sanitizing procedures of cooking ovens

- Washing and sanitizing processes COP

- Processes of intervention and sanitizing of meat or egg

- Washing and sanitizing methods of direct application or with foaming

- Washing and sanitizing processes of ultrafiltration membranes

- Dry cleaning and sanitizing processes

- Washing and sanitizing processes of baskets, containers, and pallets

- Methods of cleaning and sanitizing of molds

- Transport washing and sanitizing processes

- Chain lubrication processes

- Paw scalding processes

- Viscera washing and sanitizing processes

- Treatments to extend shelf life

- Yielding plant treatments

- Measures to prevent cross-contamination and sanitary laundry

- Passivation processes

Choose a comprehensive solution

Technical support

Expert consultants who will be able to provide technical advice and solve microbial contingencies.

Product Technology

Specialized and certified products. Designed to remove specific dirt.

Equipment

State-of-the-art equipment for the application of our products and thus achieve productivity at the best cost.

Comments or Questions?

Thanks for your interest in Rosmar! We look forward to hearing from you.

Sectors we serve

Gestation

Incubators and hatchers

Breeding

Farms and stables

Slaughter

Traces

Processing

Packers and workshops

Cooking

Fully cooked plants

Distribution

DC’s: Meat Distribution Centers

By-products eggs

Egg products